Mines are dangerous places, and coal mines are the most dangerous of all. In one coal mining accident in China in 1942 more than 1500 Chinese forced laborers were killed in an incident which began as a fire. The Japanese mine administrators sealed the mine to extinguish the fire, and the majority of the men working in the mine died from carbon monoxide poisoning from the flames. When the Japanese reopened the mine it took additional Chinese forced laborers over a week to extract all of the bodies of the dead. It was the worst mining disaster in history, little known since it occurred during the Second World War.

Mine disasters have eliminated whole towns and villages, as in Pennsylvania’s Centralia Mine Fire, which has been burning underground since it was started accidentally in 1962. Early attempts to control the fire failed and it now covers more than 3,700 acres underground, and is expected to burn for another two and a half centuries before exhausting itself. Pennsylvania seized the borough of Centralia under eminent domain and by 2013 only seven residents remained, with smoke and coal gases rising from ruptures in the streets and fissures in the earth, caused by the burning coal seam beneath.

Here are ten examples of the disasters which struck miners as they worked deep within the earth, in the history of American mining.

The Indian Territory Mine Disasters

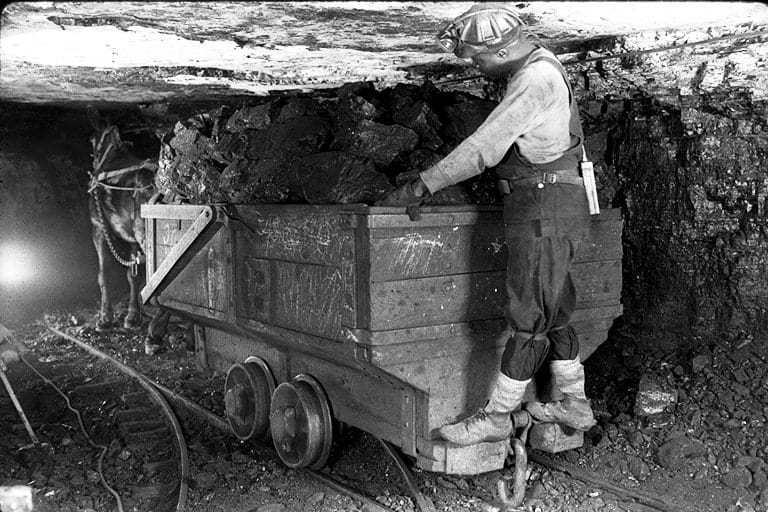

During the period when Oklahoma was known as the Indian Territory, its coal mines were, measured by the number of accidents they endured, the most dangerous in the United States. Between 1867 and 1906, in order to be termed a “disaster” in the Indian Territory mines, at least five miners had to have been killed. During that time 187 miners died in disasters, while scores and probably hundreds died, individually or in smaller groups in the mines. Mines could kill in a number of ways, including explosions, fires, floods, toxic gases, collapse, falls, and tram accidents. The rate of deaths in the mines of the Indian Territory were more than twice that of neighboring Kansas.

There was also the possibility of death from what the miners called a “windy shot”. In those days of blasting using black powder, rather than the safer dynamite, a miner first excavated a hole in the coal seam, after which it was packed with black powder, which had to be tamped down. If the miner improperly tamped the powder, or if he used too much powder, the explosion caused a blowback of sparks and flame, which could easily ignite the methane gas or the coal dust present in the mine. Windy shots were well known, occurring with a frequency which made them a tragic though not wholly unexpected event in the mines.

It was a windy shot which ignited the Indian Territory’s worst mining disaster in 1892, near Krebs. The Osage Coal and Mining Company operated its Mine Number 11 at the location. The mine, as were most mines in the Indian Territory was notorious for the buildup of methane gas, a problem which had led to several disasters before that of Krebs. A poorly prepared black powder charge resulted in a windy shot which ignited the gas in the mine, and the flash explosion swept through the mine before there was time to react. One hundred men were killed outright, and another two hundred men in the mine were injured.

The Krebs mine explosion was one of several which occurred in the Indian Territory, where the mines were unregulated and the miners’ were unorganized labor. Demand for proper ventilation of the mines, to reduce the buildup of methane gas and thus the potential for explosions was non-existent. In the aftermath of the Krebs explosion, miners began to lobby for safer working conditions. They found support from the federal government in Washington, which created a position for a mining inspector for the Indian Territory in response to the disaster. The position did little to improve conditions in the mines.

The main role for the mining inspector was to document accidents and disasters after they occurred, rather than to take steps to avoid them. There was little authority over the operation of the mines, which remained in the hands of their owners. The mines of the Indian Territory continued to experience an inordinate share of accidental detonations of coal dust and methane gases, even after the arrival of organized labor, which lobbied for better working conditions. Even the adoption of the safer dynamite to blast did not fully eliminate the problem, as other ignition sources continued to ignite methane pockets.